Designing a Watch

From an idea to your wrist, see how we’re designing our next timepiece.

Chapter 1: Beginning a New Story

For this new collection, we decided to throw what we ‘always do’ out the window and focus on something bolder… inside and out. It's no surprise that we’re anxious to invest so much energy and money in this project – it’ll have the highest retail value of any watch we’ve made. But… who wants to stand still when you can go forward?

The final materials and movement aren’t set in stone, but we’re expecting the $400 (USD) range. We’re inspired by other uncompromising watch brands and decided to place this new collection under our house brand Arkai. This gives us the freedom to explore the bold, premium, ambitious vibe we’re after.

Chapter 2: Initial Sketches

The first sketches are done and – after a ton of iterations – we’ve got something we're excited about. We've designed the case to be solid stainless steel and showcase a skeleton dial. What's the point in having mechanical movement if we're hiding it?

We want to highlight the movement in all its intricate detail and add a glass back so you can watch the movement at work. We’re hyped about the direction, but we have unanswered questions: What model of movement will we have? What clasp? Where exactly should the logo be on a transparent face? Will stainless steel make the watch too heavy?

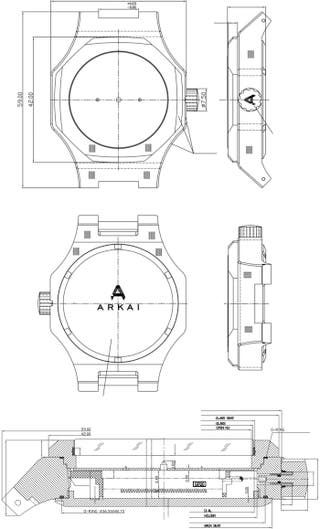

Chapter 3: Completing Specs & Sketches

We’ve settled on a case design and are closer to a dial design and hands that fit the style. As you can see, the crown will have the Arkai A engraved. It’s one of the small details that isn’t obvious, but it gives the wearer that something extra.

The case will likely be made out of at least 2 parts because the top piece is designed with angles and facets. Will it increase cost? Probably. Is it worth it? Most certainly.

We've also specced initial measurements that may change when we see the 3D model.

- Dial diameter: 32 mm (1 1/4")

- Bezel diameter: 42 mm (1 5/8")

- Case thickness: 12.5 mm (1/2")

Chapter 4: Final Touches Before Sampling

Now comes the fun part. We take the sketches and specs and transform them into digital designs for the manufacturer. It’s our chance to explore colors and the finer details like the finish on the solid stainless steel – we went with brushed for an upscale look.

Speaking of important details, we’re going with a top-of-its-class Miyota 8N24 mechanical movement, hard sapphire glass, and long-wearing surgical stainless steel.

- Miyota 8N24 Skeleton Mechanical Movement – the heart of the watch and the key to its accuracy

- Sapphire glass – for the highest level of scratch-resistance

- Solid 316L Stainless steel case and strap (non-folded steel)

- We also decided to name this automatic mechanical watch, Mateo. Say hello, world.

What would a Limited Edition look like? If you were to make a limited edition, what would that be? Comment here and let us know.

Chapter 5: Technical Details & 3D Prints

In some ways, making a watch is easier than you might expect. In other ways, it seems like an insurmountable task. Take the case and dial for example. Once they’re in place, you have to find a movement that fits. If it doesn’t… you’re back to sketching dials and cases. We try to foresee obstacles, but like making whiskey… it’s not until everything comes together that you know what you’ve got.

One of the ways we keep our costs down (and yours!) is by 3D printing the case. You’d be surprised how much difference a millimeter can give to the overall impression of a watch. Using a 3D render lets us see the dimensions and proportions and play around with color and material.

Above, you’ll see the 3D render of the watch case. What would happen if we gold plated the bezel?

Chapter 6: The Little Brother

Just for fun, we wanted to explore how a quartz version of this watch would look. It would be cheaper and, if we’ve nailed the design, still give off the premium vibe. We saved time sketching because the case didn’t change and we could play around with the dial digitally.

We decided to go with a moon-phase dial and Miyota 6P20 movement for its beautiful depth and to give you full control from the crown. It was important to keep the profile clean and similar to its older brother, Mateo.

You’ll notice that the small details, like the engraved A are still there… as well as the long-wearing materials like sapphire glass and surgical steel. This battery-operated edition is named Mace.

If you designed a watch, what would you name it? Comment and let us know.

Chapter 7: Designing an Experience

The first samples have arrived and we must admit – choosing solid 316L stainless steel and sapphire glass really made the difference. It’s something you feel instantly when you hold one of the timepieces. The weight in your hand. The way the light passes through the glass straight to the very heart of the watch. It’s worth the time spent to get here.

We’ve changed the thickness of the case for a more comfortable fit and a sleeker look.

- The Mateo with Miyota 8N24 mechanical movement: 11.6 mm (7/16")

- The Mace with moon phase and Miyota 6P20 quartz movement: 10.2 mm (3/8")

In addition to adding gunmetal to the collection, we’ve designed a Limited Edition with 999 pieces. And we’ve created packaging befitting the final product. We want you to experience this watch… not just put it on.

Final production is underway and at this rate, you’ll have one on your wrist before you know it.

Chapter 8: New Styles Available Now

The wait is over!

We’re proud to introduce the latest additions to our collection of men’s watches – carefully crafted from surgical-grade stainless steel and sapphire glass. Fueled by accurate movements from Miyota.

Check out the complete collection below.